Loading Please Wait

Loading Please Wait

The only training center with 100% passing rate for TESDA NCII and can offer actual industry based experience to our graduates in THI.

BMC’s present strength lies primarily in its being chosen as TESDA’s Official Testing Venue for the student welders and the expertise of its owner and proprietor which spans to 25 years of actual welding and metal fabrication experience.

SMAW is versatile and can be used to weld various metals, including carbon steel, stainless steel, cast iron, and non-ferrous metals. It is commonly employed in construction, fabrication, pipelines, maintenance and repair work, and other applications where portability and flexibility are required.

It’s important to note that SMAW requires skill and practice to achieve quality welds. Proper safety precautions, such as the use of protective gear and ensuring good ventilation, are essential to protect the welder from hazards associated with welding, including intense heat, UV radiation, and fumes.

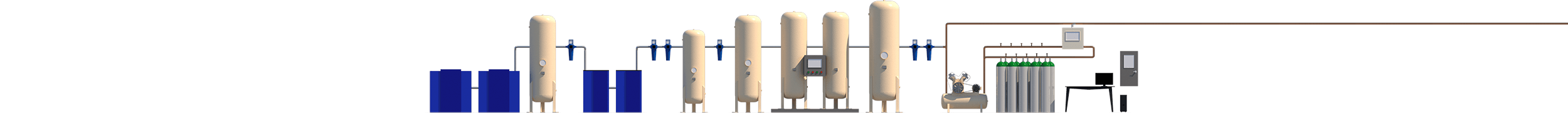

Industrial pipefitting is a skilled trade that involves the installation, assembly, and maintenance of piping systems in industrial settings. Pipefitters are responsible for working with pipes, valves, fittings, and other components to create systems that transport fluids, gases, or solids within industrial facilities.

Industrial pipefitting is essential in a wide range of industries, including oil and gas, chemical plants, power generation, manufacturing, and construction. Pipefitters often work closely with engineers, welders, and other skilled tradespeople to ensure the proper installation and functioning of piping systems, contributing to the efficient and safe operation of industrial facilities.

Gas Tungsten Arc Welding (GTAW) is a precise and versatile arc welding process that uses a non-consumable tungsten electrode to create a high-temperature arc for melting and fusing metal.

It’s important to note that GTAW/TIG welding requires skill and practice to achieve high-quality welds. The process demands a steady hand, good coordination, and control over various parameters. Safety precautions, including protective gear, proper ventilation, and awareness of the risks associated with welding, should always be followed.

Gas Metal Arc Welding (GMAW), also known as Metal Inert Gas (MIG) welding, is a widely used arc welding process that involves the use of a consumable electrode wire and a shielding gas. GMAW is known for its versatility, high productivity, and ease of use, making it one of the most popular welding methods in various industries.

GMAW is known for its efficiency and versatility, making it suitable for a wide range of applications. It is commonly used for welding automotive parts, structural components, pipes, tanks, and many other metal fabrication projects. Skilled welders can produce high-quality welds with good mechanical properties using the GMAW process.

Oxygen and acetylene welding, also known as oxyacetylene welding or oxy-fuel welding, is a welding process that uses a combination of oxygen and acetylene gases to create a high-temperature flame for melting and joining metal. It is an older welding technique that is still used in certain applications today.

It’s worth noting that other welding processes, such as Gas Metal Arc Welding (GMAW/MIG) and Gas Tungsten Arc Welding (GTAW/TIG), have gained popularity and are often preferred over oxygen and acetylene welding due to their ease of use, efficiency, and versatility. However, oxyacetylene welding is still valued for its portability, ability to work in remote locations, and its suitability for specific applications where precise heat control and softer welds are desired.

Flux-Cored Arc Welding (FCAW) is a welding process that falls under the category of arc welding. It is similar to other arc welding methods like Shielded Metal Arc Welding (SMAW) and Gas Metal Arc Welding (GMAW), but it has its own unique characteristics and advantages. FCAW is widely used in various industries due to its versatility and ability to weld in different positions.

Flux-Cored Arc Welding is a versatile and productive welding process that utilizes a consumable electrode wire with a flux core to create strong welds in various positions and materials. It offers advantages such as high deposition rates and all-position capability, but it requires proper technique and attention to avoid weld defects.

A Metal Fabrication Company established as Single Proprietorship Organization since the year 1990. It set up its first business address in the residence of its proprietor and owner at Lahing-lahin St., Mabolo, Cebu City. It first offered subcontracting jobs to bigger industrial plants in the neighborhood such as the shops of COACO, WG&A and others.

Big industrial plants in the region such as Keppel, Tsuneishi, Supercat and others has come to notice the company’s efficiency and high quality workmanship so that they have become its primary client.

The proprietor and owner provides the single point of contract for the client, ensuring that its tam of highly skilled men assigned to various trades such as piping, welding & fabrication, medical pipeline etc. performs well according to the clients budget and time constraints, but producing workmanship of highest technical quality.